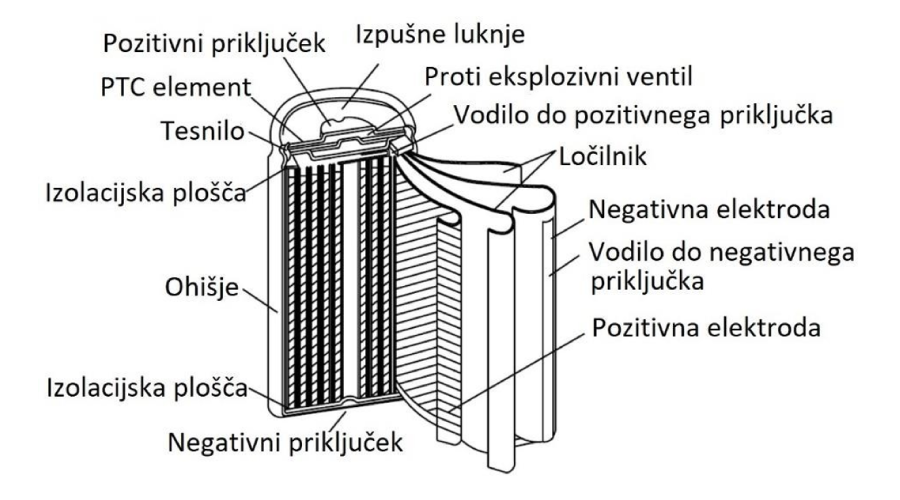

The Li-ion battery type 18650 consists of a cylindrical housing made of nickel-plated steel. The components (interior) of the cell are classified into three main groups:

Jelly roll,

Current connectors

Safety devices

The jelly roll contains a cathode (positive electrode), an anode (negative electrode) and an electrolyte (usually in a liquid state), which is added to a separator..

The separator separates the cathode and the anode and is non-conductive for electrons and conductive for ions. The cathode is made of aluminum foil. It is coated with a layer of a mixture of various metal oxides such as lithium, nickel, cobalt, manganese, iron and aluminum. Most often, cathodes are coated with::

Lithium nickel cobalt manganese oxide (LiNiCoMnO2 – a commonly used commercial abbreviation is NCM)

Lithium Nickel Cobalt Aluminum Oxide (LiNiCoAlO2 - commonly used commercial abbreviation is NCA)

Lithium Manganese Oxide (LiMn2O4 - the commonly used commercial abbreviation is LMO)

Lithium Nickel Manganese Oxide (LiNi0.5Mn1.5O4 - the commonly used commercial abbreviation is LNMO)

Lithium cobalt oxide (LiCoO2 - the commonly used commercial abbreviation is LCO)

The anode is made of copper foil. It is covered mostly with a layer of graphite. Carbon or silicon are also used. The electrolyte consists of a lithium salt in an organic solvent. It is applied to a separator made of polyethylene, polypropylene or ceramic. The thickness of the separator is usually 20 µm. The current connectors are separated into external connections, and the conductors from the electrodes to the external connections. The positive terminal is at the top of the cell. The lead to the positive terminal is a thin metal strip. Connects the positive electrode to the external terminal. It is made of aluminum alloy.

The negative connection is on the lower part of the cell. Otherwise, the entire housing except for the positive terminal is at negative potential, but the cell on the side is usually insulated with heat-shrinkable PVC film. The lead to the negative terminal or housing is a thin metal strip made of nickel alloy. It connects the negative electrode to the negative terminal and is welded to the housing.

Security components

For the correct and safe use of batteries, safety components are also built into the cells, as Li-ion batteries consist of high-energy materials and a flammable electrolyte and can pose a danger to the environment. As a result, both the European Union and the Republic of Slovenia require the general safety of all products that enter the market. There are many different security standards. The cells we used in this work have, among others, a certificate that they meet the SIST EN 62133-2:2017 standard. This certificate addresses the safety requirements for portable sealed secondary cells (meaning they can be recharged) and for battery packs made from them. The safety components are:

Cell housing. The case provides protection for the jelly roll. It protects the cell from external influences and forces, as the foils in the jelly roll are very thin and deform quickly. The case is made of stainless steel, which is nickel-plated.

- Insulation board. It is a thin round plastic plate and is used between two conductors. There are two such tiles in the cell, one below the jelly roll and one above it.

Gasket. This is an insulating material that seals the space between the positive terminal and the housing and element with a positive temperature coefficient. It therefore separates the positive and negative part of the housing, and withstands higher compression pressures (e.g. during spot welding).

An element with a positive temperature coefficient (angl. Positive temperature coefficient - PTC). It is a temperature dependent conductive element used to limit current at high temperatures. As the temperature approaches the threshold temperature, the resistance of the PTC element increases significantly. The charge/discharge current is consequently reduced. The PTC element is located between the positive terminal and the anti-explosion valve.

Anti-explosion valve is a mechanical device that prevents the cell from exploding. If the pressure inside the cell increases beyond the normal limit, the valve opens and the pressure equalizes. It is located between the PTC element and the insulating plate.

Exhaust holes are part of the ventilation system, through which the generated gases are released when the anti-explosion valve is opened.

Gases in the cell are mainly generated due to improper use, e.g. excessive charging, physical damage to the cell or internal short circuits.